In the evolving automotive industry, the choice of manufacturing techniques plays a crucial role in determining product quality, cost efficiency, and production scalability. Among the various methods used to fabricate automotive components, Automotive Injection Molding stands out as one of the widely adopted and technically refined processes. This article offers a balanced comparison between Automotive Injection Molding and other common manufacturing techniques such as thermoforming, blow molding, compression molding, and die casting, with a focus on their suitability for automotive applications.

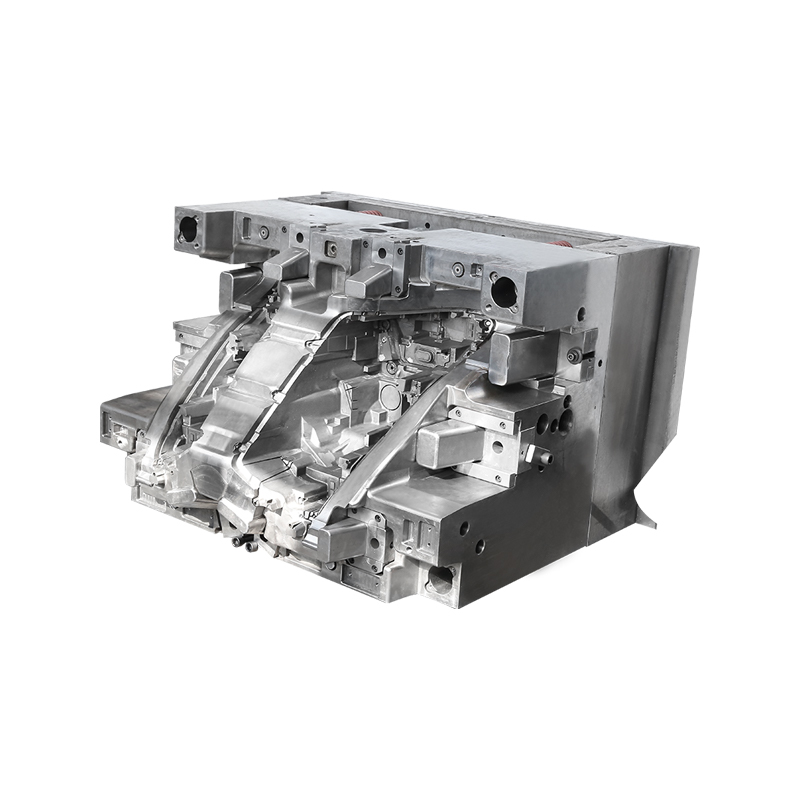

Automotive Injection Molding involves injecting molten thermoplastic materials into a steel mold to form complex, precise parts. It is particularly valued for its ability to produce high-volume, consistent components with tight tolerances. Interior panels, dashboards, bumpers, and HVAC parts are just a few examples of where Automotive Injection Molding is commonly applied. In contrast, other methods offer different strengths, often making them more suitable for specific design requirements or material types.

Thermoforming, for example, uses heat and vacuum to shape plastic sheets over a mold. While this technique allows for faster tooling and is often used in prototyping or low-volume production, it falls short when it comes to detailed features or consistent dimensional accuracy. Compared to thermoforming, Automotive Injection Molding delivers surface quality, durability, and part repeatability, especially for high-performance interior and under-hood components.

Blow molding, another plastic-forming process, is often used to manufacture hollow parts like fuel tanks and washer fluid reservoirs. While ideal for such geometries, blow molding is limited in terms of the complexity it can achieve. Automotive Injection Molding, by contrast, supports more intricate designs, tight junctions, and integrated fastening features—all essential in modern vehicle platforms where space and weight are at a premium.

Compression molding, widely used for thermoset plastics and composite materials, is effective for producing large structural components, such as underbody shields or battery enclosures. However, this method typically requires longer cycle times and greater manual handling. Automotive Injection Molding, while less suited for certain composite applications, offers a higher degree of automation, reducing labor costs and improving overall consistency.

Die casting, predominantly used for metal components, excels in strength and thermal conductivity, making it essential for drivetrain housings and heat sinks. Still, die casting is not a substitute for plastic-based designs. Automotive Injection Molding provides advantages in terms of weight reduction, corrosion resistance, and design flexibility when working with engineered thermoplastics.

From a cost perspective, Automotive Injection Molding offers clear benefits in mass production. Once the mold is manufactured, the cost per part decreases significantly as volumes increase. In contrast, some alternative methods incur higher per-unit costs due to slower cycle times or greater material waste. Furthermore, Automotive Injection Molding allows for multi-cavity tools and overmolding techniques, enabling the creation of multi-functional components in a single process—an advantage not easily achieved with many competing technologies.

Another critical consideration is material compatibility. Automotive Injection Molding supports a wide range of polymers, including ABS, PP, PA, PC+ABS, and glass-fiber reinforced resins, which are commonly used across interior, exterior, and functional applications. This versatility enables OEMs and Tier 1 suppliers to achieve both aesthetic and mechanical performance goals.

In summary, while each manufacturing method has its role in the automotive sector, Automotive Injection Molding remains the preferred choice for producing high-volume, precision plastic parts. Its unique balance of speed, repeatability, and material flexibility makes it especially suitable for today’s demands in automotive design, where lightweighting, modularity, and cost efficiency are critical. As technologies continue to advance, Automotive Injection Molding is expected to remain a central pillar in automotive production strategies for years to come.

English

English 中文简体

中文简体 русский

русский Español

Español