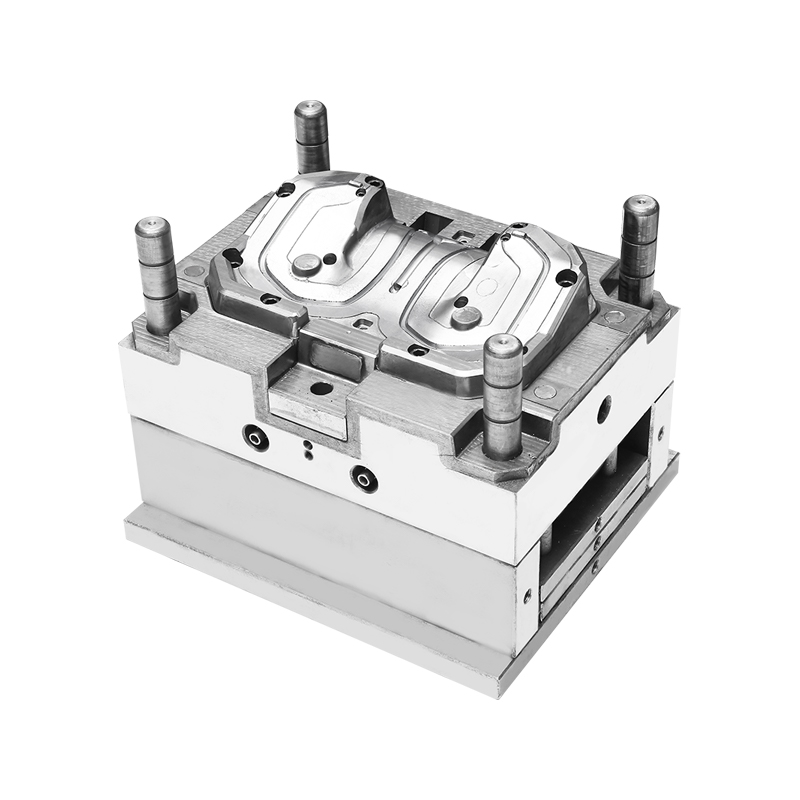

In the automotive industry, the significance of high-quality auto lamp moulds cannot be overstated. These molds are crucial in shaping the intricate and precise components of car lamps, which are essential for both aesthetics and functionality. The choice of materials for auto lamp moulds is a critical factor that directly impacts their durability, precision, and overall performance.

Commonly, auto lamp moulds are manufactured using specific types of steel, such as P20 and 718. These materials are favored for their toughness and machinability. P20 steel, for instance, is known for its balance of strength and ease of processing, making it ideal for creating complex shapes and designs required for modern auto lamps. Similarly, 718 steel offers mechanical properties, ensuring that the auto lamp moulds can withstand the pressures of repeated use without compromising on quality.

However, selecting the right material is just the step. Ensuring the stability of the material's performance is equally important. This is where heat treatment processes come into play. Proper heat treatment is vital for enhancing the hardness and wear resistance of auto lamp moulds. By subjecting the moulds to carefully controlled heating and cooling cycles, their microstructure is refined, resulting in improved mechanical properties.

For example, a well-executed heat treatment can significantly increase the hardness of the mould surface. This enhanced hardness not only reduces the risk of wear and tear during the production process but also minimizes the likelihood of deformation. As a result, the auto lamp moulds can maintain their precision over a longer period, ensuring that each lamp produced meets the exact specifications required.

Moreover, the stability of the material's performance also contributes to the consistency of the final product. When auto lamp moulds are made from high - quality materials and undergo precise heat treatment, they can produce lamps with uniform quality. This consistency is crucial in the automotive industry, where safety and reliability are paramount.

In recent years, advancements in material science and heat treatment technologies have further improved the performance of auto lamp moulds. New alloy compositions and innovative heat treatment techniques are constantly being developed to push the boundaries of what these moulds can achieve. For instance, some manufacturers are exploring the use of advanced high-strength steels that offer even better wear - resistance and dimensional stability.

These improvements have a direct impact on the automotive industry. With more durable and precise auto lamp moulds, manufacturers can produce high - quality lamps more efficiently. This not only reduces production costs but also enhances the overall quality of the vehicles. As a result, consumers can enjoy safer and more reliable cars, knowing that every component, including the lamps, has been manufactured to the standards.

The choice of materials and the heat treatment processes for auto lamp moulds are key factors in ensuring their durability and precision. By using high - quality materials like P20 and 718 steel and employing advanced heat treatment techniques, manufacturers can create auto lamp moulds that stand the test of time. This commitment to material excellence not only benefits the automotive industry but also ensures that consumers receive products of the quality.

English

English 中文简体

中文简体 русский

русский Español

Español