Car body moulds play a crucial role in shaping the aerodynamic and safety characteristics of modern vehicles. These moulds are used to create various components, from bumpers and body panels to more intricate parts like spoilers and wings, all of which significantly influence how a vehicle performs on the road.

Aerodynamics

Aerodynamics is a key consideration in car design, as it affects fuel efficiency, stability, and overall performance. Car body moulds enable the creation of streamlined shapes that reduce drag and improve airflow around the vehicle. For example, the design of the front and rear wings, which are often made using moulds, can generate downforce, enhancing high-speed handling and traction. The use of spoilers, another component typically created with car body moulds, can also improve aerodynamics by reducing lift and increasing downforce, particularly at high speeds.

Safety

Safety is another critical aspect influenced by car body moulds. Components such as bumpers and body panels, which are often produced using these moulds, are designed to protect the vehicle’s structure and occupants during collisions. The materials used in these moulds, such as thermoplastic olefin (TPO) and polycarbonate/acrylonitrile butadiene styrene (PC/ABS) blends, are chosen for their durability and impact resistance. This ensures that these components can absorb and distribute impact forces effectively, reducing the risk of injury to passengers.

Design and Manufacturing

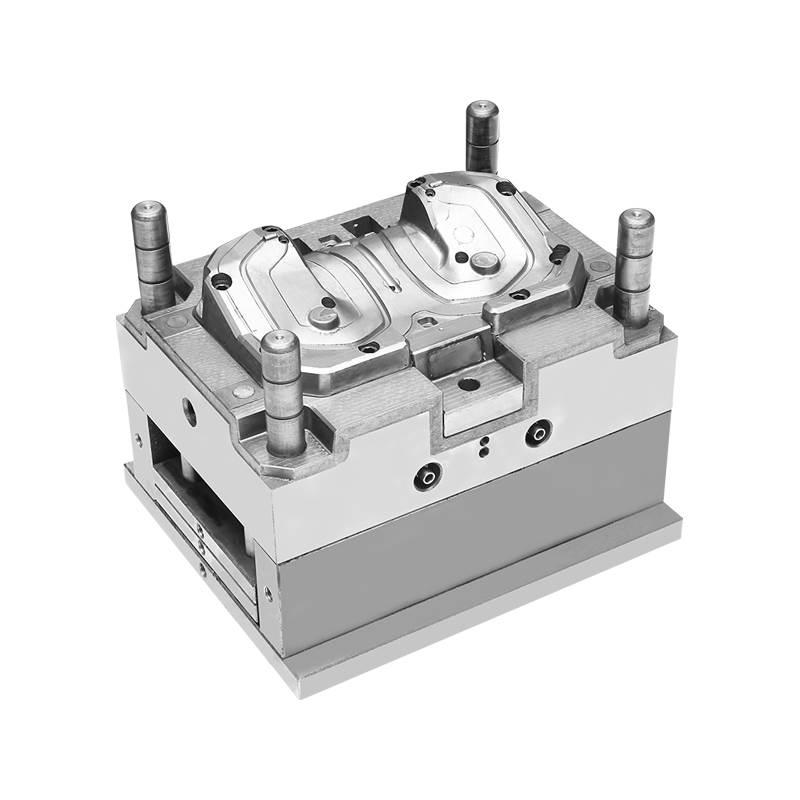

Car body moulds allow for the production of complex geometries and integrated features, which are essential for both aerodynamic efficiency and safety. For instance, the nosecone of a vehicle, which is the point of contact with the air, can be designed to redirect airflow in a way that enhances performance and cooling. These moulds are often created using advanced techniques like CNC machining and carbon fiber layups, ensuring high precision and durability.

Real-World Applications

In motorsports, where aerodynamics and safety are paramount, car body moulds are used to create components that provide a competitive edge. For example, adjustable rear spoilers can significantly enhance the aerodynamic performance of a vehicle, improving stability and reducing braking distances. Similarly, in everyday vehicles, the use of aerodynamic body panels and bumpers can improve fuel efficiency and reduce wind noise, enhancing the overall driving experience.

Future Developments

As technology advances, the role of car body moulds in enhancing vehicle aerodynamics and safety will continue to evolve. Future developments may include the use of lightweight materials like carbon fiber composites, which can optimize performance without adding excess weight. Additionally, the integration of active aerodynamic systems, which can adjust in real-time to driving conditions, will further enhance the capabilities of vehicles.

In conclusion, car body moulds are essential in the design and manufacturing of vehicles, influencing both aerodynamic performance and safety. By enabling the creation of complex and efficient components, these moulds contribute to the development of safer, more efficient, and higher-performing vehicles. As the automotive industry continues to innovate, the importance of car body moulds in achieving these goals will only grow.

English

English 中文简体

中文简体 русский

русский Español

Español