In the modern automotive industry, efficiency, precision, and durability are essential factors in producing high-quality vehicle components. Among the many manufacturing processes used in the sector, Plastic Injection Mold technology has become an indispensable solution, particularly for parts such as bumpers, dashboards, door panels, and other interior trims. The use of Plastic Injection Mold ensures that these components meet functional, aesthetic, and safety requirements while supporting large-scale production needs.

Precision and Consistency in Bumper Manufacturing

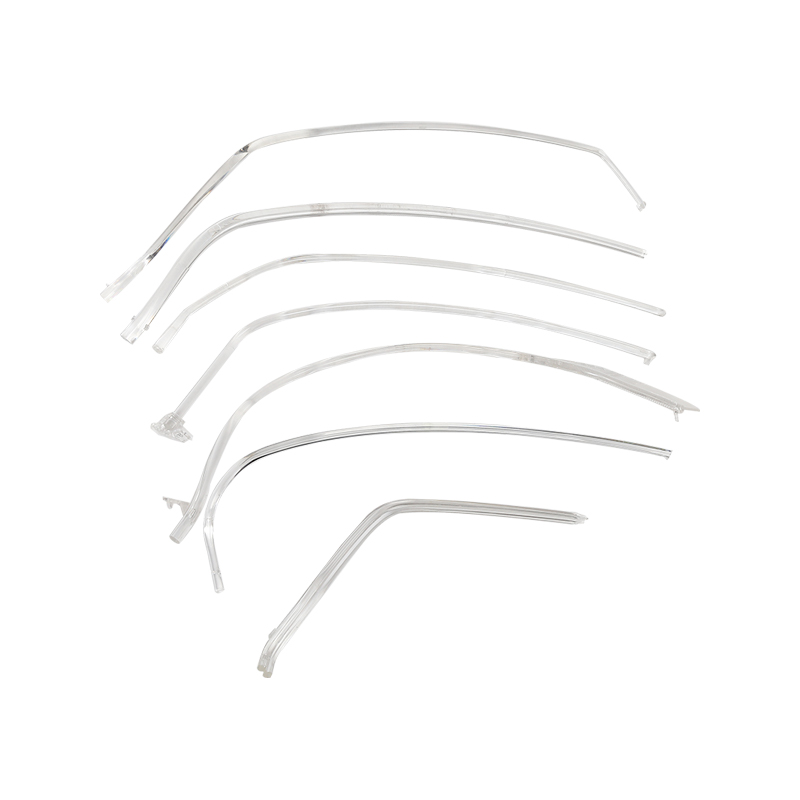

Bumpers are among the visible and functionally critical parts of any vehicle. They must withstand impact, maintain aerodynamic performance, and integrate seamlessly with the vehicle's overall design. The Plastic Injection Mold process is ideally suited to produce bumpers due to its ability to deliver consistent dimensions and surface quality across thousands of units.

A well-designed Plastic Injection Mold allows for the creation of large, complex bumper shapes with tight tolerances. The mold cavity is engineered to manage material flow, cooling, and ejection in a way that minimizes warping, sink marks, and weld lines. By using high-performance thermoplastics such as PP (polypropylene) or ABS, the Plastic Injection Mold can deliver bumpers that are lightweight yet impact-resistant.

Moreover, multi-cavity or two-plate Plastic Injection Mold designs enable the simultaneous production of different sections of a bumper assembly, reducing production time and improving part uniformity.

Enhancing Interior Trim with Plastic Injection Mold

Vehicle interiors are designed with both comfort and aesthetics in mind. Dashboards, console panels, door trims, and air vent housings are all typically produced using Plastic Injection Mold methods. These parts often require textured surfaces, soft-touch finishes, and integration with electronic components such as switches or touchscreens.

The flexibility of Plastic Injection Mold allows manufacturers to incorporate these requirements into a single molded part. From the choice of resins to mold surface treatments, every detail can be tailored for the specific needs of an interior part. For instance, a dashboard produced with a textured Plastic Injection Mold can replicate the look and feel of leather or brushed metal without the added cost of post-processing.

In addition, Plastic Injection Mold supports overmolding processes, which allow for combining soft and hard materials in one component. This is especially useful in parts like armrests or control knobs, where user touchpoints require ergonomic surfaces.

Material Versatility for Automotive Standards

The automotive industry uses a wide variety of plastic resins, each selected based on mechanical strength, UV stability, thermal resistance, and chemical durability. A robust Plastic Injection Mold system is designed to handle these materials without compromising cycle time or product quality.

Materials commonly used in Plastic Injection Mold applications include PC/ABS blends, TPOs (thermoplastic polyolefins), and glass-filled nylon. Each of these materials performs differently under injection pressure and mold temperature, and the mold design must accommodate those behaviors. Proper gating, venting, and temperature control within the Plastic Injection Mold ensure defect-free surfaces and dimensional stability.

Cost Efficiency in Mass Production

Automotive manufacturing demands consistent quality at competitive costs. Plastic Injection Mold offers one of the cost-effective methods for producing high volumes of parts. Once the mold is fabricated, the cost per part decreases significantly with each production cycle.

For components like bumpers and interior trims, where thousands or even millions of parts may be required annually, Plastic Injection Mold ensures scalability without sacrificing quality. Automation and robotics further enhance productivity, as many Plastic Injection Mold setups are integrated into fully automated production lines.

Durability and Long Mold Life

Molds used in the automotive sector are built to last. A typical Plastic Injection Mold for bumper production may run hundreds of thousands of cycles over its lifetime. To support this longevity, mold components are often constructed from high-grade tool steel, treated for hardness and corrosion resistance.

Regular maintenance of the Plastic Injection Mold, such as cleaning, polishing, and lubrication, ensures long-term dimensional accuracy and surface finish quality. For manufacturers, the durability of the mold translates to reduced downtime and lower long-term tooling costs.

Supporting Customization and Design Flexibility

Consumer expectations in the automotive market often drive manufacturers to offer more personalized designs and frequent updates. Plastic Injection Mold technology supports this demand by allowing design changes through modular mold inserts or rapid tooling adjustments.

Whether a car model requires a new trim style or a region-specific bumper shape, the Plastic Injection Mold can be modified accordingly without replacing the entire mold base. This adaptability helps automakers respond quickly to market trends and regulatory requirements.

The use of Plastic Injection Mold in automotive parts manufacturing is essential for meeting modern demands of precision, efficiency, and aesthetic quality. From robust bumpers to detailed interior panels, Plastic Injection Mold technology enables cost-effective, high-volume production of critical components. As automotive design continues to evolve, the importance of Plastic Injection Mold will only grow, offering manufacturers the flexibility and reliability needed to stay competitive in a dynamic industry.

English

English 中文简体

中文简体 русский

русский Español

Español