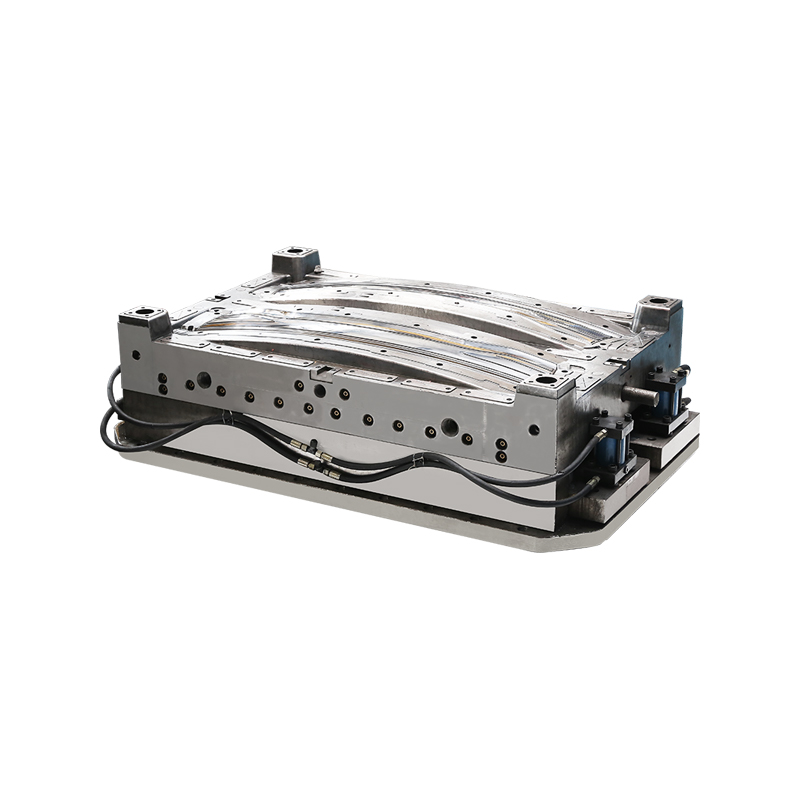

The automotive industry is at the forefront of innovation, with a constant demand for high-quality, efficient, and cost-effective solutions. Car Part Mold plays a pivotal role in meeting these challenges, providing manufacturers with the tools to create complex and intricate components with precision and speed. In this article, we will explore the significance of customization and flexible production in the realm of Car Part Mold, highlighting how these factors are shaping the future of automotive manufacturing.

The Importance of Customization in Car Part Mold:

Customization is no longer a luxury but a necessity in the competitive automotive market. Car Part Mold providers must offer a range of services that cater to the unique needs of each client. By doing so, they can ensure that the molds produced are not only tailored to the specific requirements of each vehicle model but also maintain the standards of quality and performance. Car Part Molds that are designed with customization in mind can accommodate the diverse needs of various automotive brands, from compact cars to heavy-duty trucks.

The Advantages of Modular Design in Car Part Mold:

Modular design in Car Part Mold has revolutionized the way components are manufactured. This approach allows for the easy adjustment and modification of molds, making it simpler to adapt to the ever-changing demands of different vehicle models. By employing modular Car Part Mold, manufacturers can reduce downtime and increase efficiency, as components can be quickly reconfigured without the need for a complete overhaul of the mold. This flexibility is crucial in an industry where time to market is a critical factor.

Technological Support for Rapid Response and Small-Batch Production:

Advancements in technology have been instrumental in supporting the rapid response and small-batch production capabilities of Car Part Mold. Modern Car Part Mold facilities are equipped with machinery like CNC machines, which can quickly produce molds with high precision. Additionally, the integration of digital technologies, such as 3D printing, has allowed for the creation of complex Car Part Molds with intricate details, further enhancing the customization capabilities of the molds.

The Role of Materials Science in Car Part Mold:

Materials science plays a significant role in the development of Car Part Mold. The selection of the right materials can affect the durability, strength, and overall performance of the molds. High-quality materials ensure that Car Part Molds can withstand the pressures and temperatures encountered during the manufacturing process, while also being cost-effective. The ongoing research in materials science is to the discovery of new materials that can further improve the efficiency and longevity of Car Part Molds.

The Impact of Customization and Flexibility on the Automotive Industry:

The ability to offer customized Car Part Mold solutions has a profound impact on the automotive industry. It not only allows for the production of parts that are perfectly suited to each vehicle model but also enables manufacturers to respond quickly to market changes and consumer demands. This agility is essential in an industry where trends and preferences can shift rapidly. By embracing customization and flexibility, Car Part Mold providers are positioning themselves as key players in the future of automotive manufacturing.

Challenges and Solutions in Car Part Mold Production:

Despite the many advantages, the production of Car Part Molds also presents challenges. One of the main issues is the high initial investment required for the machinery and technology involved. However, this investment is often offset by the long-term benefits of increased efficiency and reduced production costs. Another challenge is ensuring the quality and consistency of Car Part Molds across different production runs. This can be addressed through rigorous quality control measures and the implementation of industry standards.

The Future of Car Part Mold:

Looking ahead, the future of Car Part Mold is promising. As technology continues to advance, we can expect to see even greater levels of customization and flexibility in Car Part Mold production. The integration of artificial intelligence and machine learning into Car Part Mold systems will further enhance the efficiency and accuracy of the molds. These advancements will not only improve the manufacturing process but also contribute to the overall sustainability of the automotive industry by reducing waste and increasing the lifespan of the parts produced.

In conclusion, Car Part Mold is a critical component in the automotive industry's drive towards customization and flexible production. By investing in advanced technology, materials science, and modular design, Car Part Mold providers are well-equipped to meet the diverse and evolving needs of the market. As the industry continues to innovate, Car Part Mold will play an increasingly vital role in shaping the future of automotive manufacturing, ensuring that vehicles are not only efficient and reliable but also tailored to the specific requirements of their users.

English

English 中文简体

中文简体 русский

русский Español

Español