In the high-stakes world of mass manufacturing, consistency isn't just desirable; it's the bedrock of profitability, brand reputation, and customer satisfaction. Nowhere is this truer than in plastic injection molding, where the quality of the Plastic Injection Mold itself stands as the single critical factor determining the uniformity of millions of identical parts rolling off production lines. Understanding this direct cause-and-effect relationship is fundamental for any business relying on this ubiquitous manufacturing process.

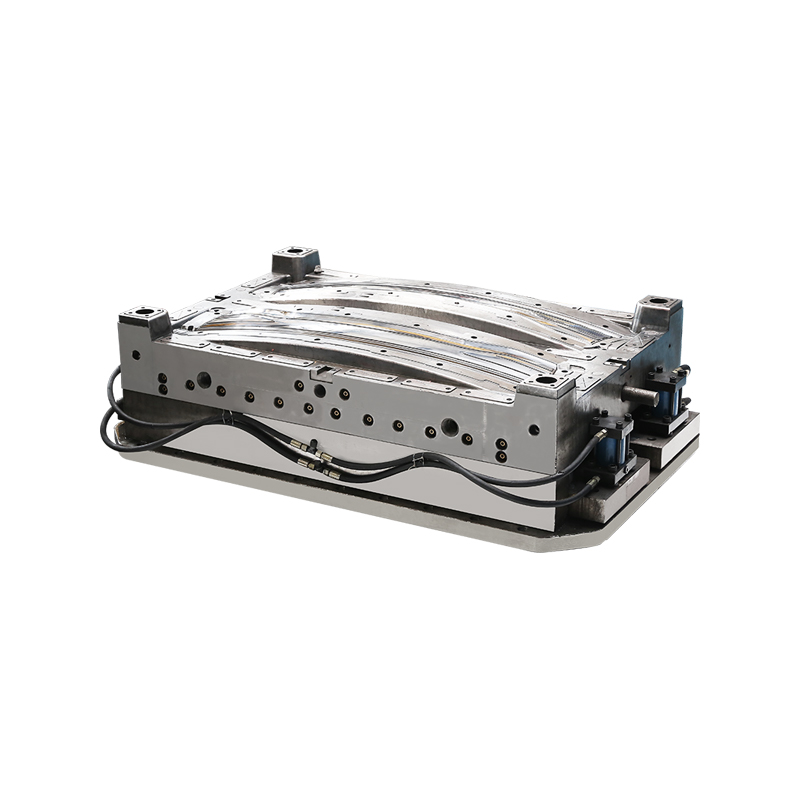

At its core, a Plastic Injection Mold is a precision-engineered tool, typically crafted from hardened steel or aluminum. It defines the final shape, surface finish, dimensions, and structural integrity of the plastic part. When molten plastic is injected under high pressure into the cavity formed by the Plastic Injection Mold, every minute detail of that mold's design and construction is imprinted onto the cooling polymer. Consequently, any imperfection, deviation, or inconsistency within the Plastic Injection Mold is faithfully reproduced in every single part it produces.

The Precision Imperative:

High-quality Plastic Injection Molds are manufactured to exacting tolerances, often measured in microns (thousandths of a millimeter). This precision ensures that every cavity within a multi-cavity Plastic Injection Mold is identical. If cavity dimensions vary even slightly due to poor machining or wear, the resulting parts will exhibit dimensional inconsistencies – some too large, some too small, some warped. This directly impacts assembly, function, and interchangeability. Achieving part-to-part consistency across thousands or millions of cycles demands a Plastic Injection Mold built and maintained to the standards.

Material Flow and Cooling: The Hidden Architects of Consistency

Beyond shape, the internal design of the Plastic Injection Mold governs the flow of molten plastic and its subsequent cooling. The gate design (where plastic enters the cavity), runner system (channels distributing plastic), and venting (allowing air to escape) must be optimized. A poorly designed or manufactured Plastic Injection Mold can to uneven filling. This causes variations in density, internal stresses, and potentially visible defects like weld lines or air traps, compromising the part's strength and appearance inconsistently.

Equally critical is the cooling system. Efficient, uniform cooling is vital for controlling part shrinkage and preventing warpage. Channels within the Plastic Injection Mold circulate coolant. If these channels are poorly placed, uneven, or become clogged over time, different areas of the part cool at different rates. This non-uniform cooling inevitably s to dimensional variation and warping from one part to the next. A high-quality Plastic Injection Mold incorporates a meticulously engineered cooling layout, often verified through mold flow analysis software before metal is cut.

Durability and Wear: The Long-Term Consistency Challenge

The demanding environment inside a Plastic Injection Mold – high pressure, high temperature, abrasive polymers, and constant cycling—subjects the tool to significant wear. A high-quality Plastic Injection Mold starts with premium tool steels, hardened and often surface-treated (like nitriding or chrome plating) to resist abrasion and corrosion. A substandard mold, using inferior materials or inadequate hardening, will degrade faster. Key areas like gates, ejector pins, and cavity surfaces wear down, to progressive changes in part dimensions (flash, increased part size), surface finish degradation (scratches, dullness), and potential sticking or ejection problems. This wear directly erodes the consistency achieved when the Plastic Injection Mold was new. Investing in a robust Plastic Injection Mold from the outset extends its consistent production lifespan significantly.

Surface Finish and Aesthetics:

The surface finish of the cavity within the Plastic Injection Mold is directly transferred to the plastic part. A flawlessly polished or textured mold surface yields consistent, high-quality aesthetics. Any imperfection in the mold's surface – a pit, scratch, or inconsistent texture – will be replicated on every single part, creating visible blemishes or variations unacceptable for consumer-facing products. Maintaining the pristine surface quality of the Plastic Injection Mold cavity is paramount for cosmetic consistency.

The Cost of Inconsistency:

The repercussions of a poor-quality Plastic Injection Mold are severe and costly. Inconsistent parts to:

High Rejection Rates: Parts failing dimensional checks or visual inspection must be scrapped or reworked.

Assembly Issues: Parts that don't fit together properly slow down assembly lines and increase labor costs.

Performance Failures: Variations in wall thickness or internal stresses can to premature part failure in the field.

Brand Damage: Delivering products with visible defects or performance issues erodes consumer trust.

Increased Downtime: Worn or poorly functioning molds require more frequent maintenance and repairs, halting production.The Plastic Injection Mold is far more than a simple shaping tool; it is the DNA of the final product. Its quality dictates the genetic code for every part produced. Investing in a high-precision, durable, and well-maintained Plastic Injection Mold, designed and built by skilled toolmakers, is not merely an upfront cost – it is a strategic investment in long-term manufacturing stability, reduced waste, predictable quality, and ultimately, product consistency. In the competitive landscape of plastic part production, the quality of the Plastic Injection Mold remains the undeniable linchpin holding product uniformity together, cycle after cycle. Choosing anything less than a top-tier Plastic Injection Mold is a gamble with consistency that few manufacturers can afford to lose.

English

English 中文简体

中文简体 русский

русский Español

Español